The institute has extensive technical equipment at its disposal. There are dynamic engine test benches, a large number of specialised autonomous measuring systems and powerful simulation and calculation tools.

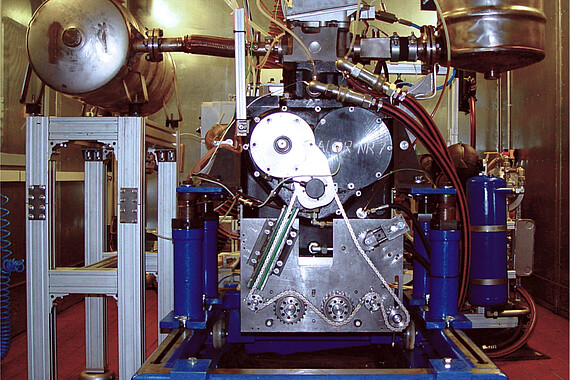

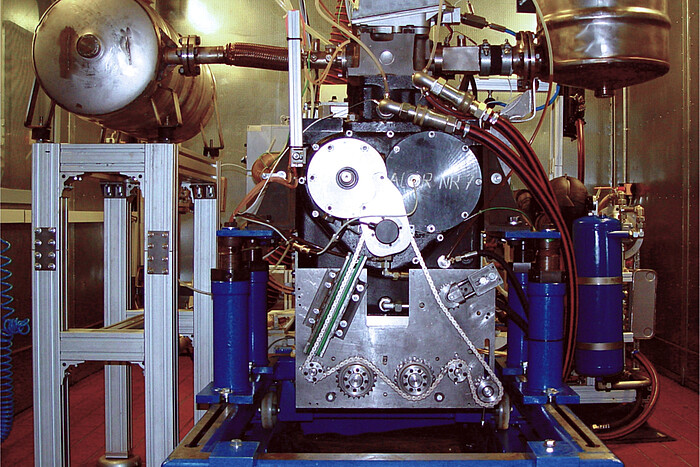

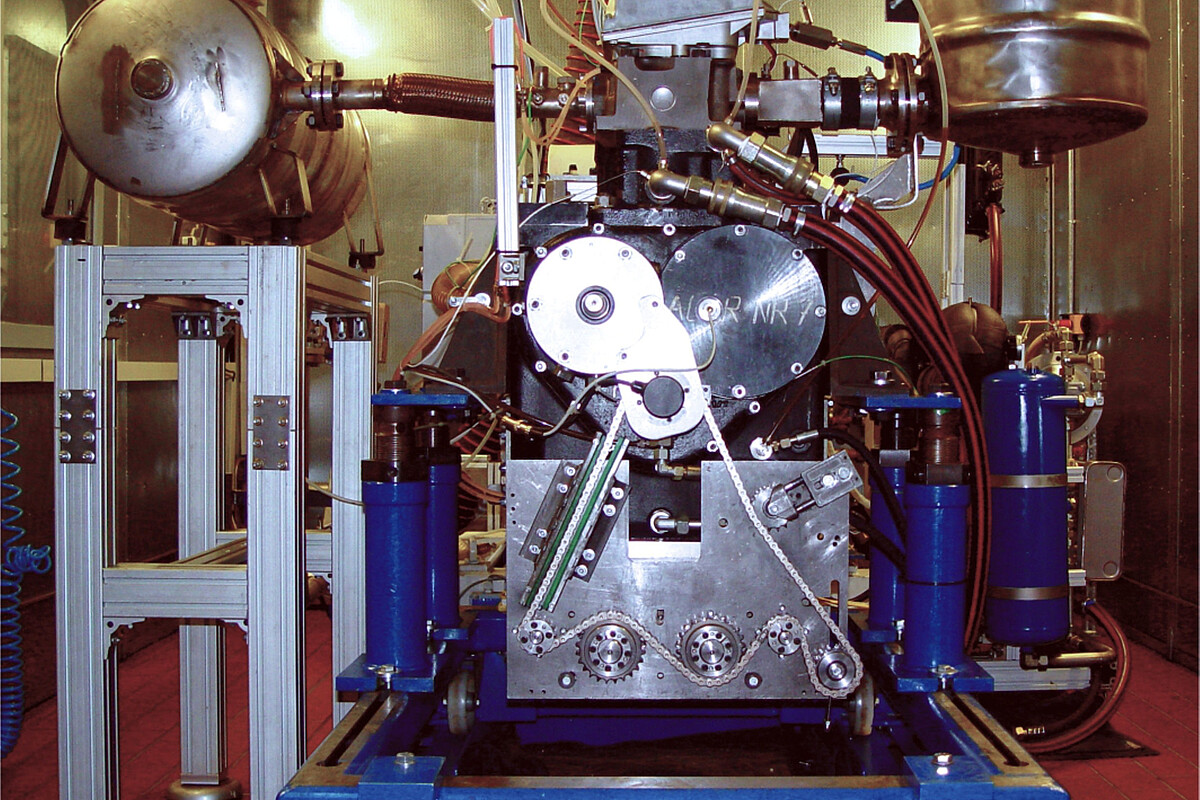

Engine Test Benches

6 engine test benches with electric load machines (4-quadrant drive) from 400 to 630 Nm torque with 200 kW power each.

- Oil, water, air and EGR conditioning. Flexible maximum pressure injection

- Programmable test bench control system

- Flexible indexing possibilities

- Fuel consumption and air mass measurement

- Exhaust gas analysis systems

- Variable pallet system

Further loading devices (2-quadrant, water vortex brake) are available.

©

Institut für Technische Verbrennung

©

Institut für Technische Verbrennung

Component Test Benches

- Injection pump test bench

- Injection curve and quantity test bench (Injection Analyser, IAV)

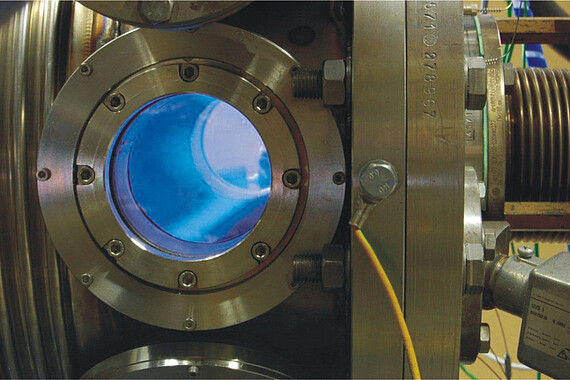

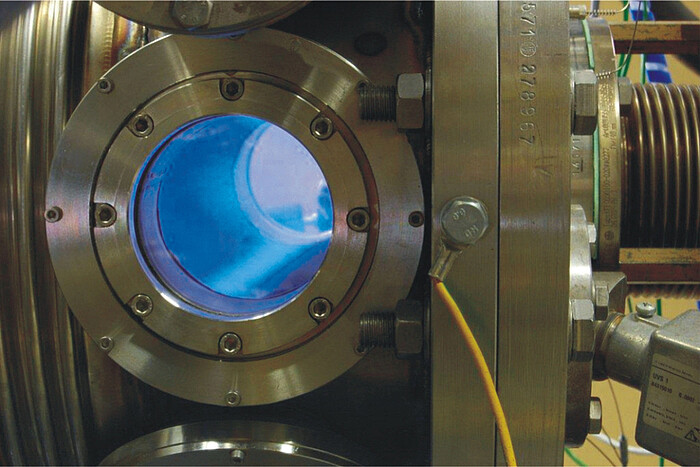

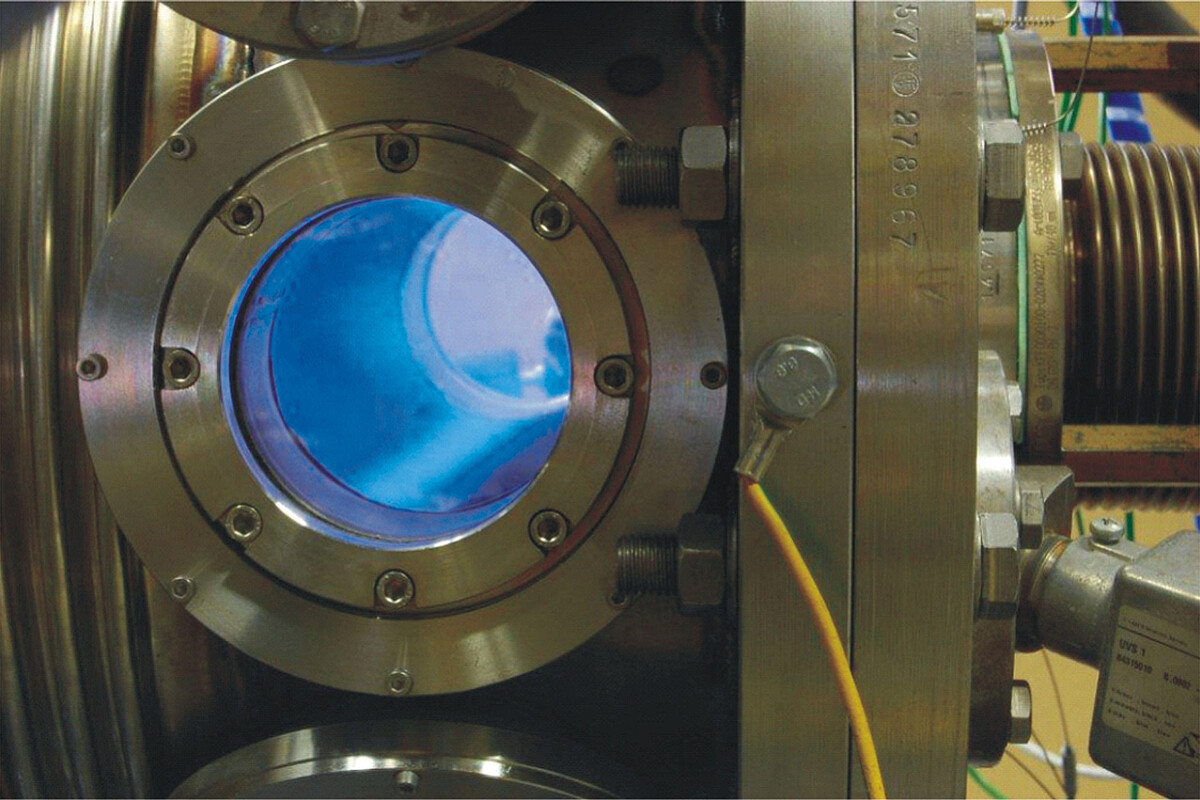

- High-pressure injection chamber for spray tests (up to 50 bar, 43 litre volume, visually accessible)

- Ignited high-pressure injection chamber for spray and ignition tests (up to 200 bar, up to 2000°C, 2.3 litre volume, optically accessible, gas mixing device)

Space is available for further component test benches.

Combustion Test Benches

- ABH 60: Flexible flame test stand up to 60 kWtherm

- ABH 200: Large test stand for turbulent flames up to 200 kWtherm (planned)

- ABH 450: Atmospheric gas turbine burner test rig up to 450 kWtherm (together with TFD-Hannover)

- High-pressure hot gas test bench with 300 mm internal diameter and up to 6 m length for operating pressures up to 3 bar (can be extended to 10 bar), with urea injection device and extensive optical measurement technology

- Small test burners (lam. firing speed, student experiments)

- Mobile exhaust gas analysis (Testo, FI detector)

©

Institut für Technische Verbrennung

©

Institut für Technische Verbrennung

Laser Measurement Technology

- Stereo-PIV-System

- High-Speed-Cameras

- High-Speed-Stereo-PIV-System

- Planar laser measurement system (Nd:YAG-Dye laser system, image-enhanced cameras) for the use of planar LIF / tracer LIF / Rayleigh / LII / and Mie measurement techniques to measure mixture formation, injection and combustion in sprays and flames

- LDA-PDA Measuring System

- Long Distance Microscope

- Fibre optic measurement technology

Measuring and Calibration Equipment

- Comprehensive sensor measuring technology

- Calibration equipment (with DKD certificate), temperature: -20 to 1200°C; pressure: 1 to 4000 bar

- Mobile Fourier transform infrared spectrometer (FTIR) for measuring exhaust gas compositions

Calculation Software

- Computational Fluid Dynamics: ANSYS-FLUENT, CONVERGE

- Combustion and kinetics calculation: Cosilab, Cantera

- Motor process calculation: GT-Power, Matlab-Simulink

- Construction: Solid Edge

- Design and FEM calculation: Creo